*Click here for Phase II * ( Whipple Design )

Cornel's 94' Formula Firebird with Custom Eaton M112 install.

I have owned this car since new and always wanted it supercharged positively. With snow performance water injection and a custom Eaton M112, Fuel Rail and intake manifold etc. I am really close to getting this running. Needless to say I am getting excited! Check it out and enjoy!.

I have been tuning and will be doing a dyno pull soon to see what she does! This thing really hauls !!

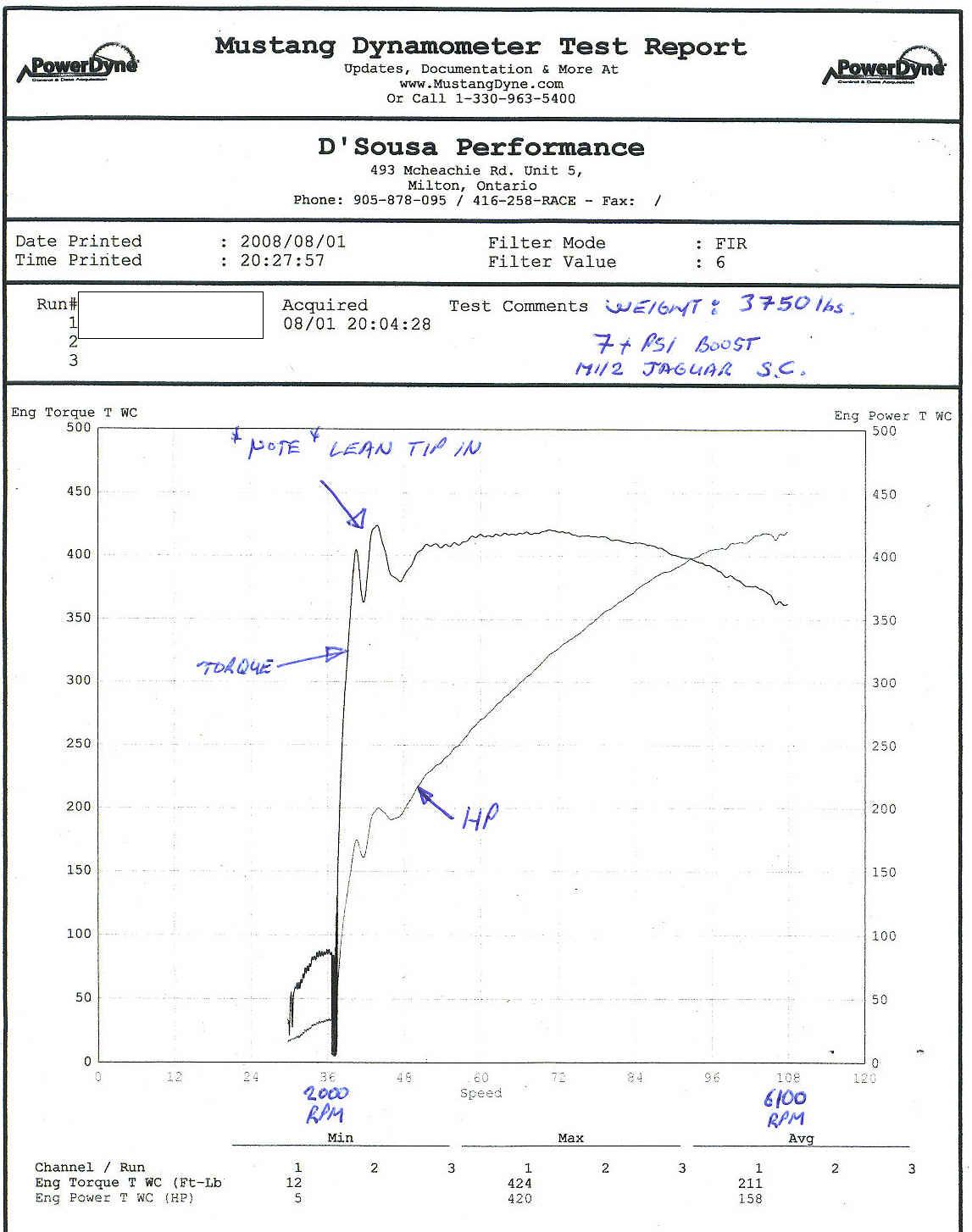

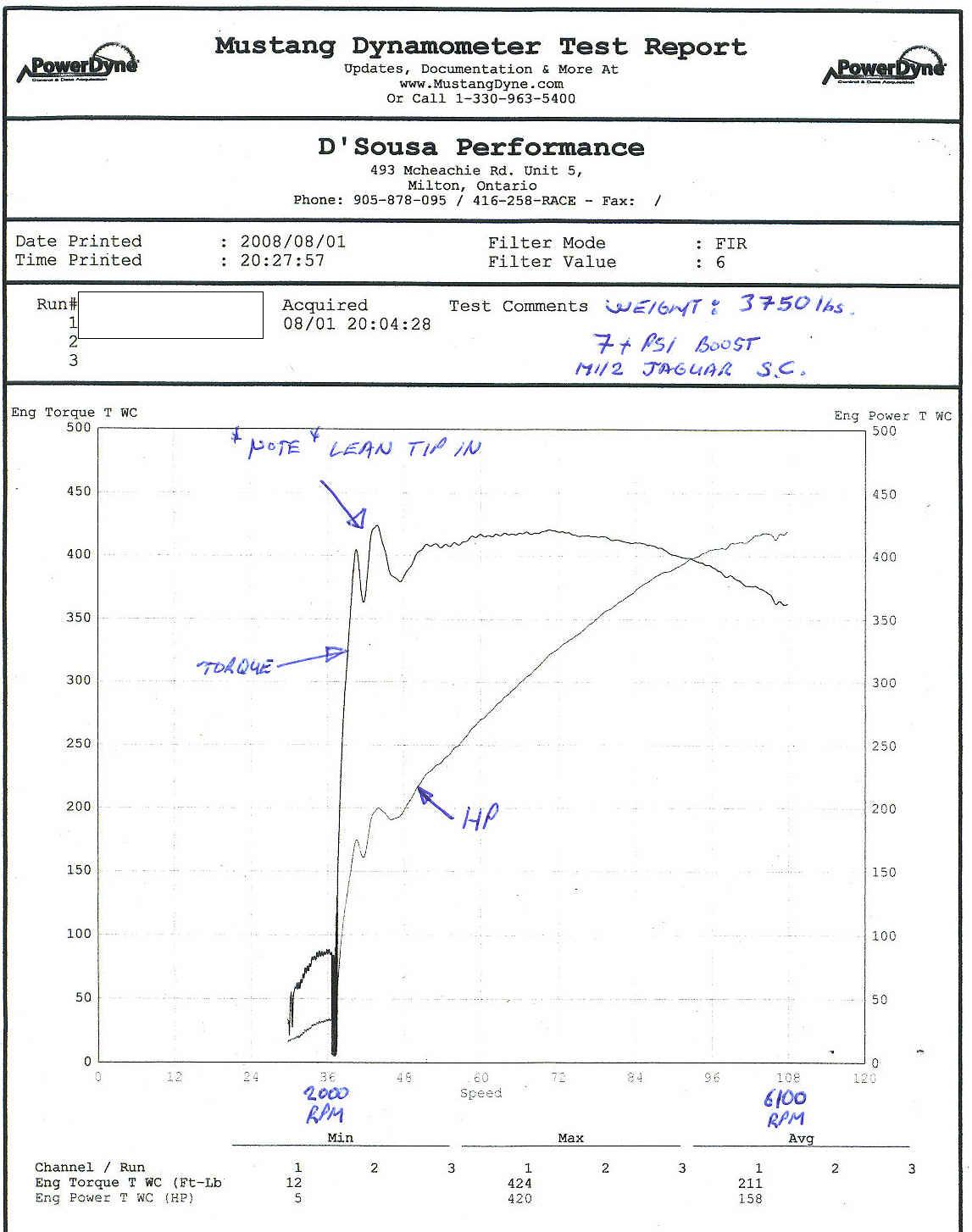

Update Aug 1/08

I have dyno tuned this car and here are the dyno results. 420 rwhp and 424 rwtq which calculates to 494HP at the flywheel and 499 Torque with 15% drive train loss. Note lean tip in causing stumble. This stumble is not there if I accelerate from a higher RPM or smoothly accelerate at low rpms. I will try to tune this out!

Engine Configuration Details:

1994 LT1 350 Cu.

Heads: Stock LT1, light porting with 918 beehive springs ARP 3/8 studs comp Pro-Mag 1.6 Roller Rockers, Comp 5/16" High Tech pushrods with LT4 guide plates and crane anti pump up roller lifters. Stock Chamber size 58cc with 1.94" intake and 1.50" Exhaust valves.

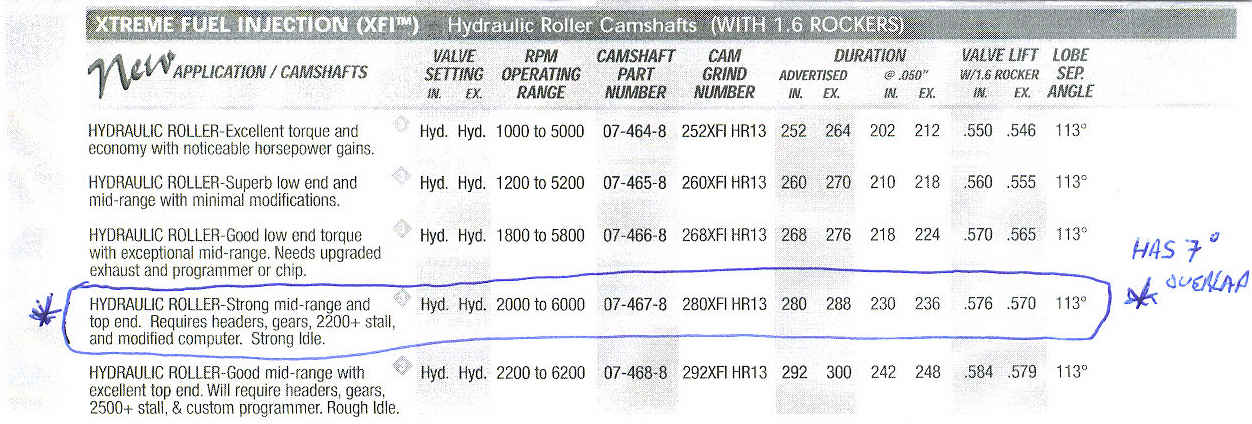

Block: Stock 4.00" bore with TRW Speed Pro -5cc Forged pistons, pressed pin. Stock Forged I beam rods 5.7" resized with ARP fasteners. Nodular Iron 350 crank balanced externally at rear. Melling High volume pump with 3/4" pickup. Two bolt mains with stock caps. GM stock timing chain and Comp 07-467-8 cam.

Ignition: GM Opti Spark (1994' type), Taylor "409 Pro Race " 10.4mm wires, NGK TR6 -IX plugs, stock coil, Crane HI-6S box with 2 bar map boost retard.

Exhaust: SLP 1 3/4" shorty headers with Y pipe to 3" SLP cat back, Magnaflow cat and Magnaflow Muffler. I hate these headers!

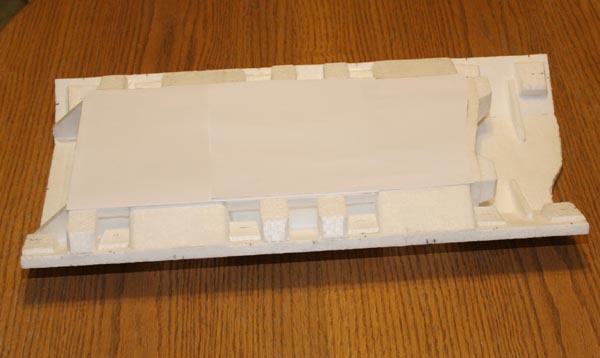

Intake manifold: Entirely custom CAD designed and fabricated from 6061-T6 aluminum welded construction, has by pass circuit , IAT sensor port, PCV port , and vac ports, 58mm LT1 BBK throttle body.

Fuel Rail: Entirely custom fabricated 3/8" stainless tubing with machined stainless injector bosses and mounting brackets, stepping down to 5/16" after pressure regulator, fits factory quick connect fittings. Aeromotive 1:1 fuel pressure regulator.

Supercharger: Jaguar XKR supercharger (Eaton M112 internals) . Modified, cut off mounting brackets and shortened nosed drive to custom length and polished and installed meth injection port.

Water/Methanol Injection: Stage II Snow performance MAF controlled Kit using 50/50 water/meth and 374ml nozzle with 150psi pump pressure.

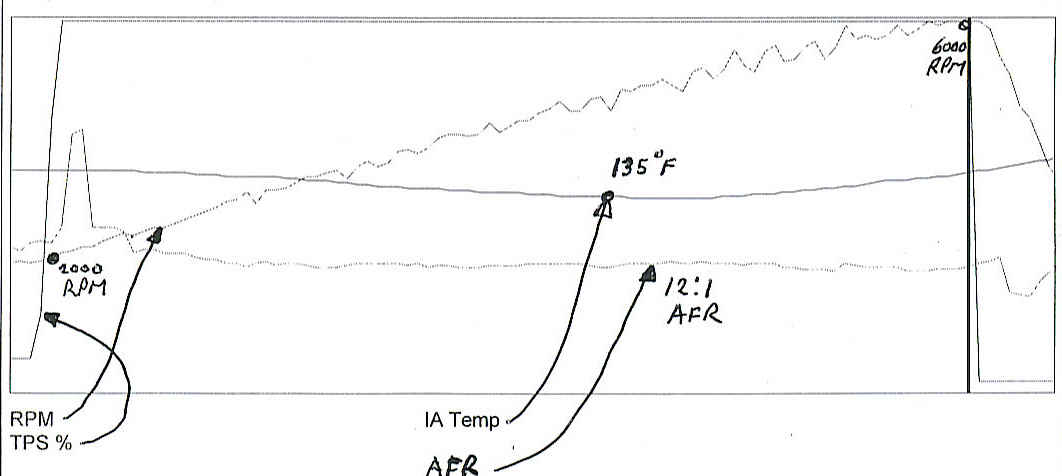

This is the AFR and intake air temp graph from my data log.

My AFR has a lean tip in to about 16:1 for and instant and then settles to 12.2:1 to 12:1 right across. The intake temps with water/meth start at 161 deg F and drop to 135 deg F and then slowly climb back to 160 deg F. There was no sign of detonation on my knock sensor @ 27 deg timing straight accross with this tune.

In conclusion I feel that the cam I used which is particularly a normally aspirated cam is wasting boost with 7* overlap. I will try a custom grind to see if there is an improvement. Secondly I think the Jaguar style M112 has a very restrictive intake port limiting cfm. I also feel that the intake duct work is too long and my ram air hood would eliminate some bends and restriction. I can't say I am disappointed but I think I can squeeze 450 rwhp and 460 rwtq from this setup with a cam change and improving the tune. The real gain is going to be phase two with the Whipple 140ax project next expecting 600 rwhp +.

Current Cam Spec Card.

Dec9/2009

Well it's been a year since my last update! Sorry for those of you following this project! I have been having a lot of fun driving my SC firebird and it has really proven itself. I decided to forget the casting process and just CNC. the new manifolds from Billet. YES Billet! I know that this sounds crazy and expensive but for now this will be the quickest way to get parts made. I am going to post pictures of my new engine that is being built by Joe D'Sousa for this new blower setup. There are many people that have e-mailed me looking for kits or manifolds and I will try to make CNC manifolds available to those people once I get this new prototype completed