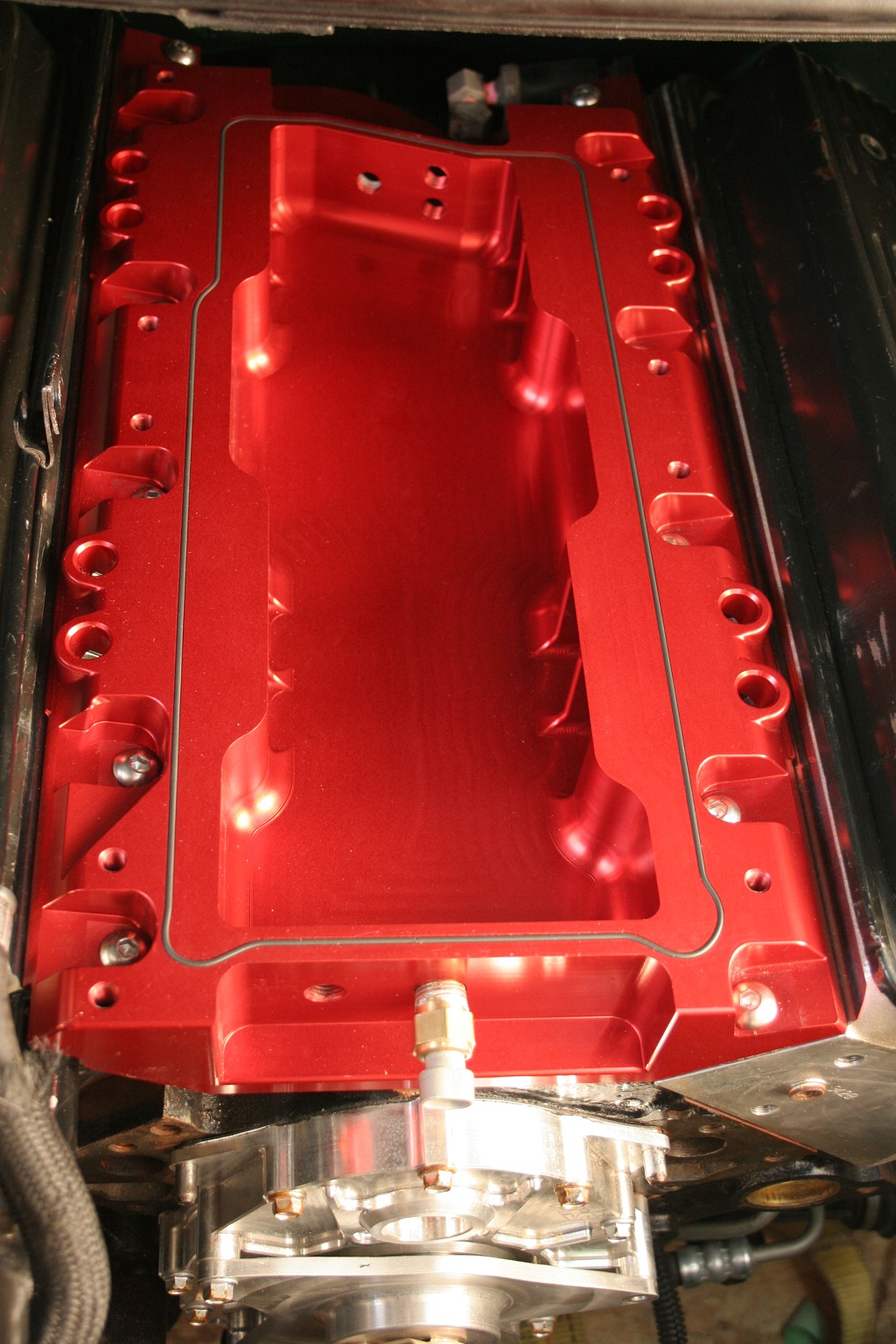

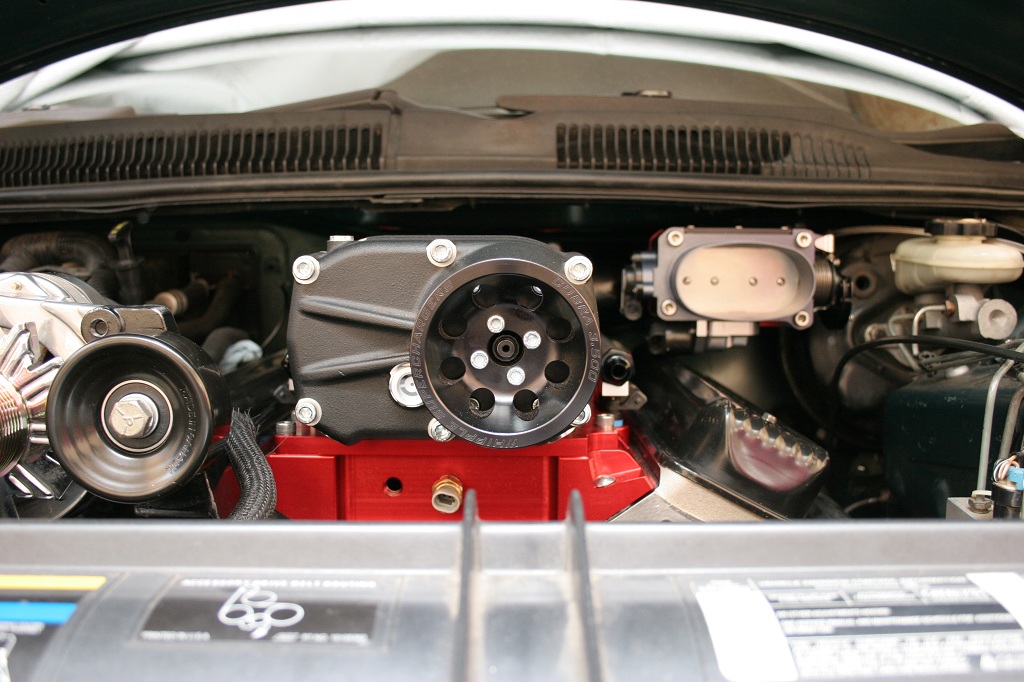

First Pics "installation on engine"

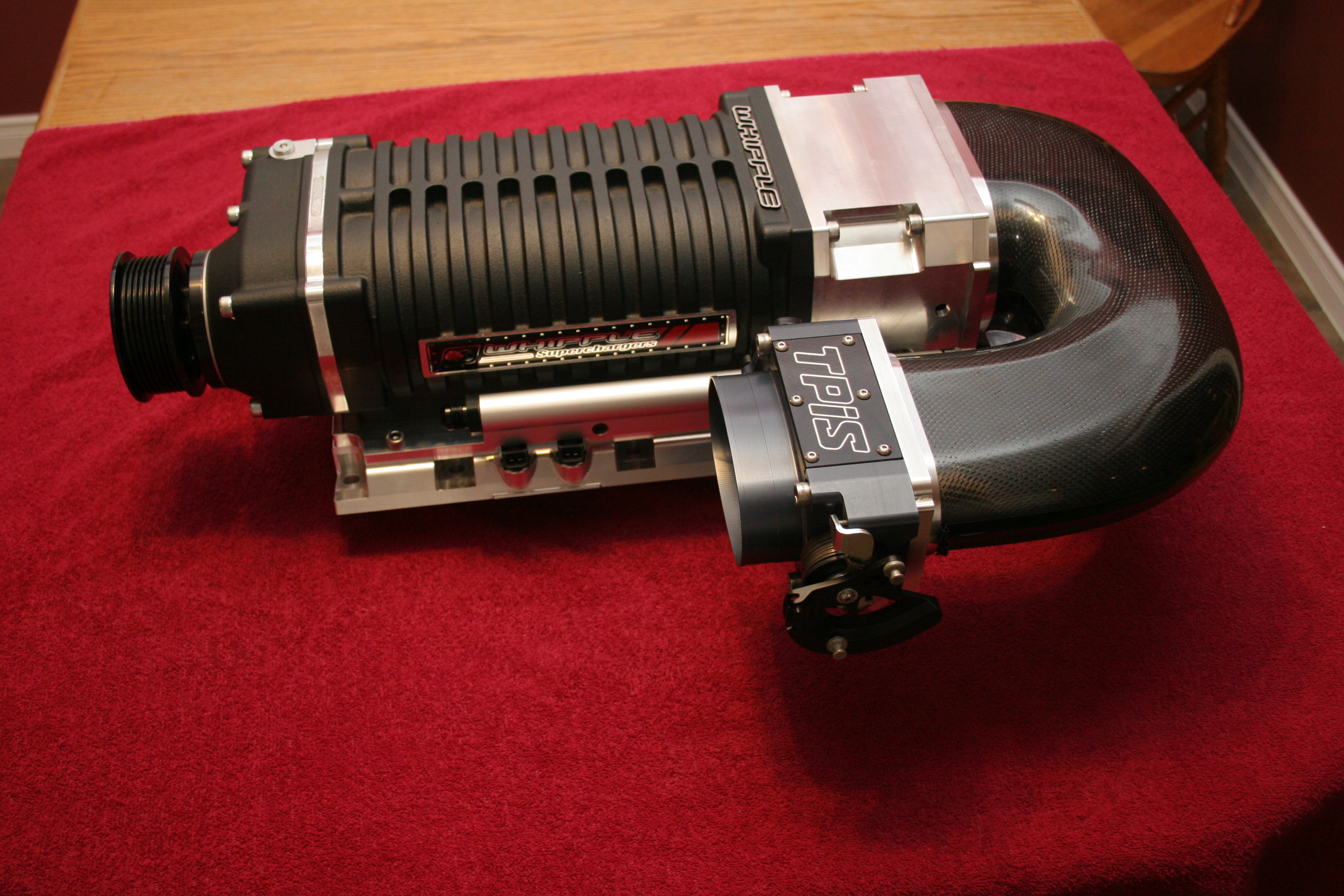

First PicsAfter Anodizing

Before Anodizing

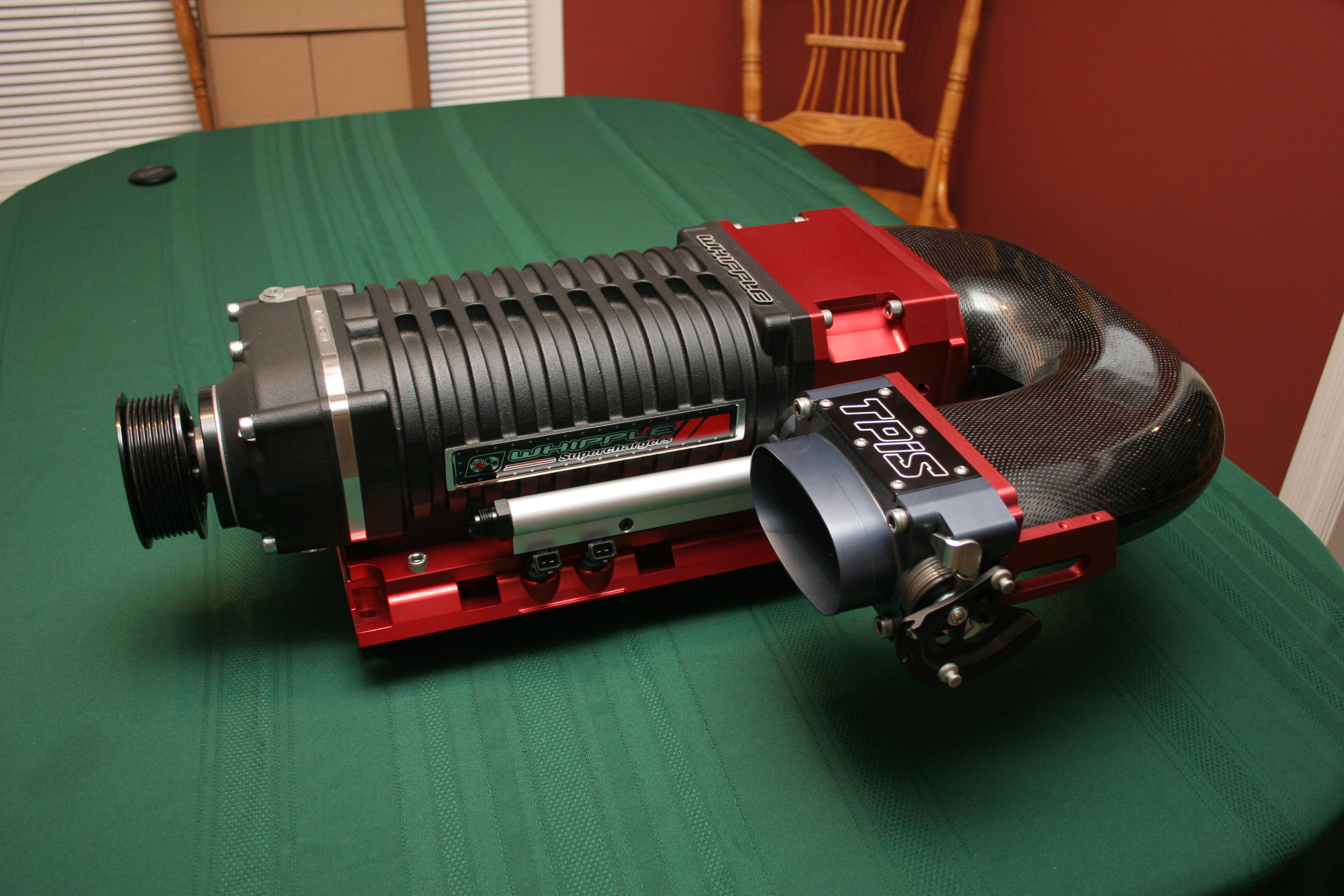

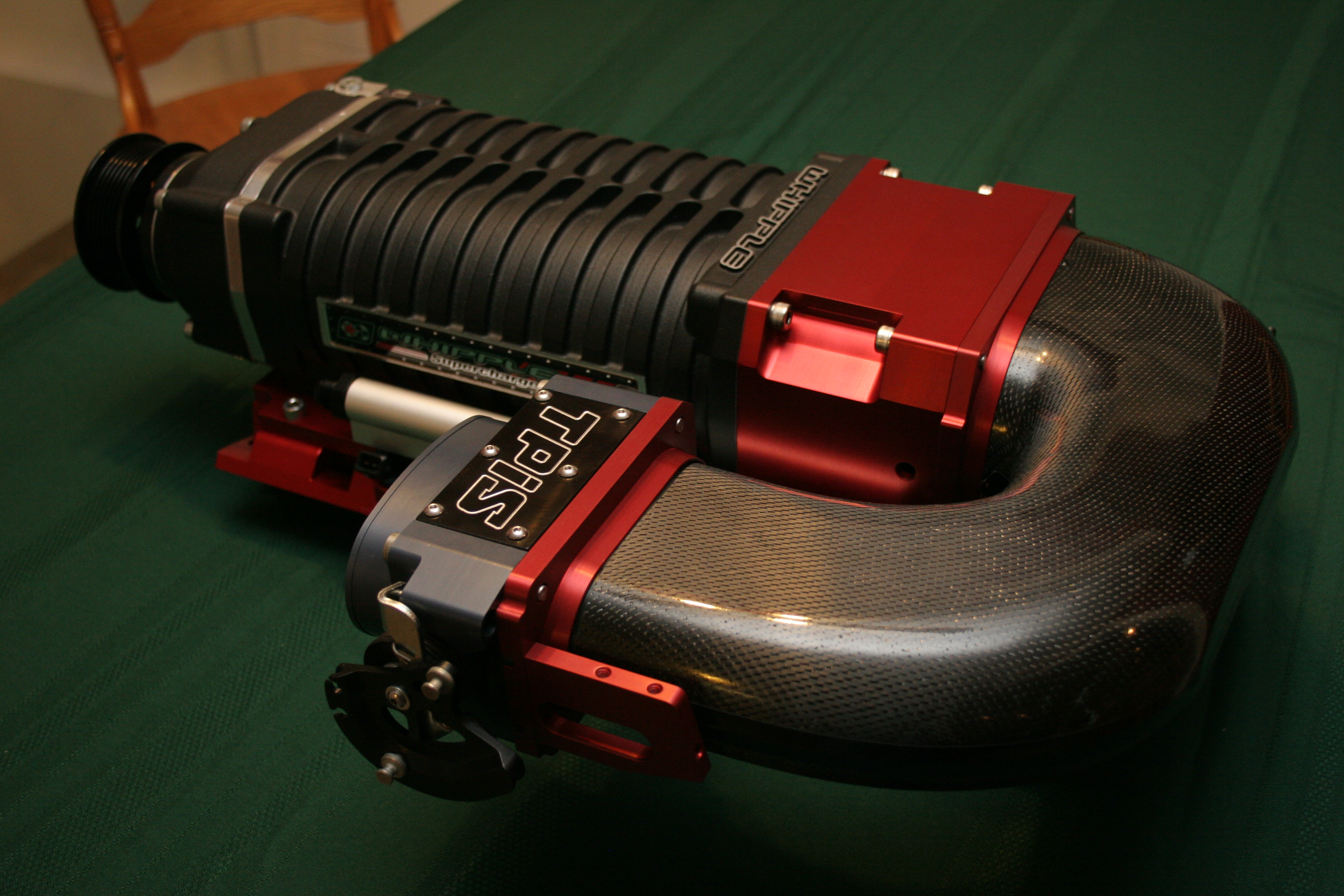

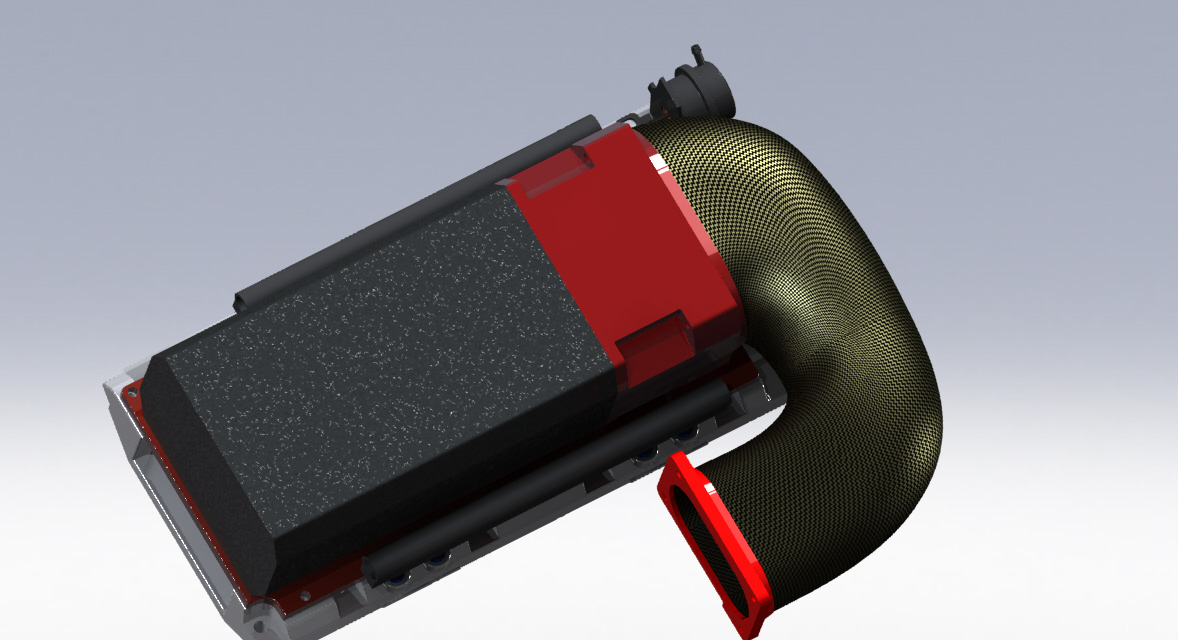

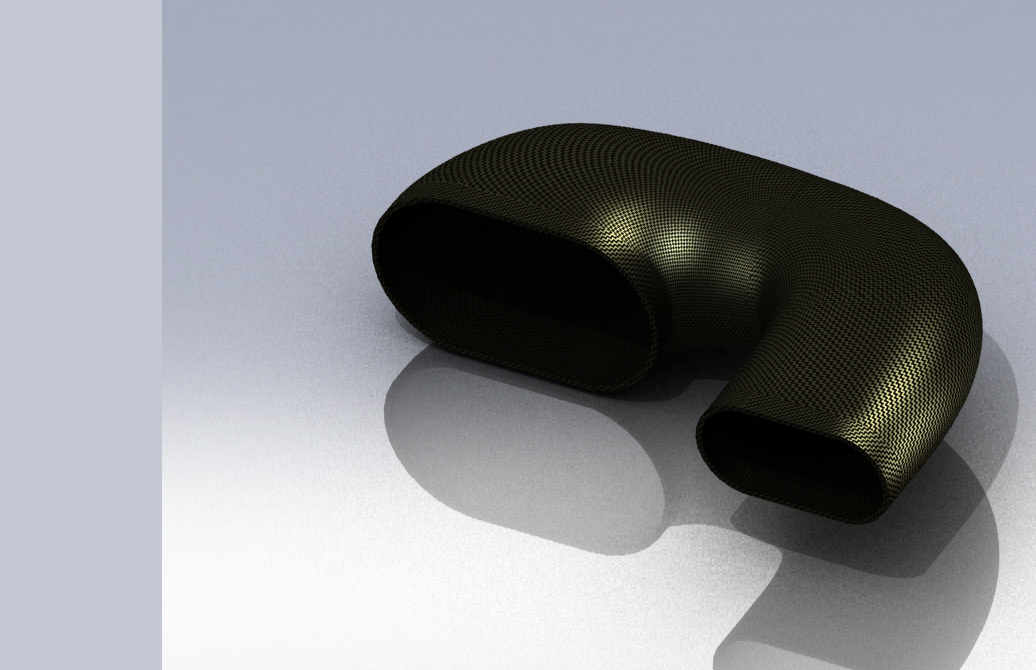

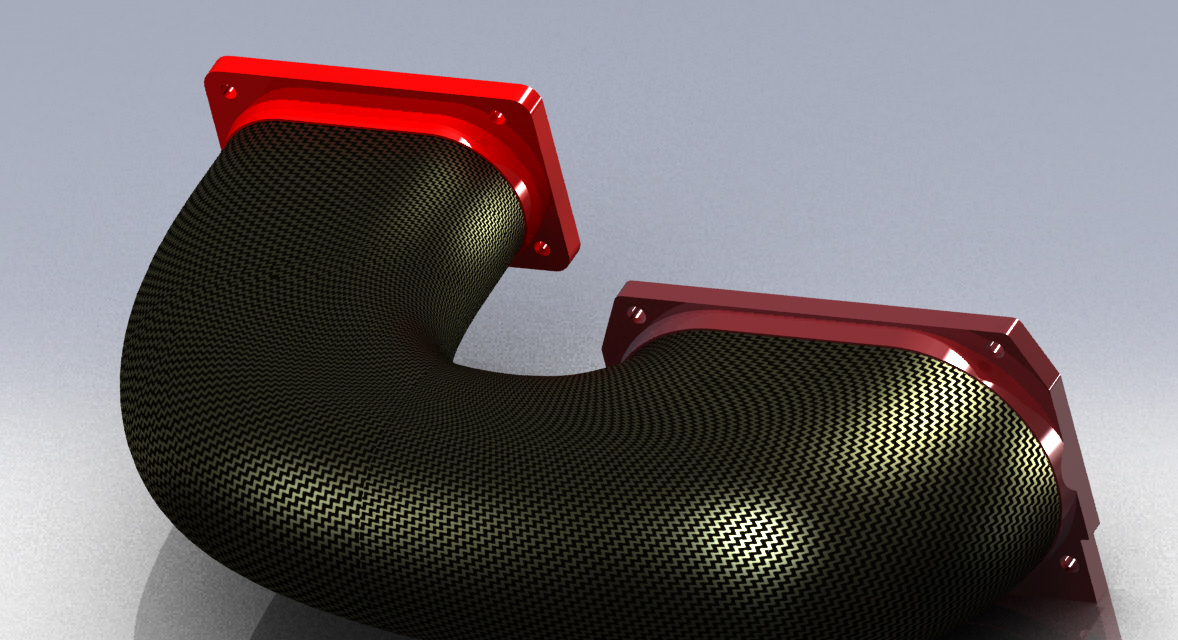

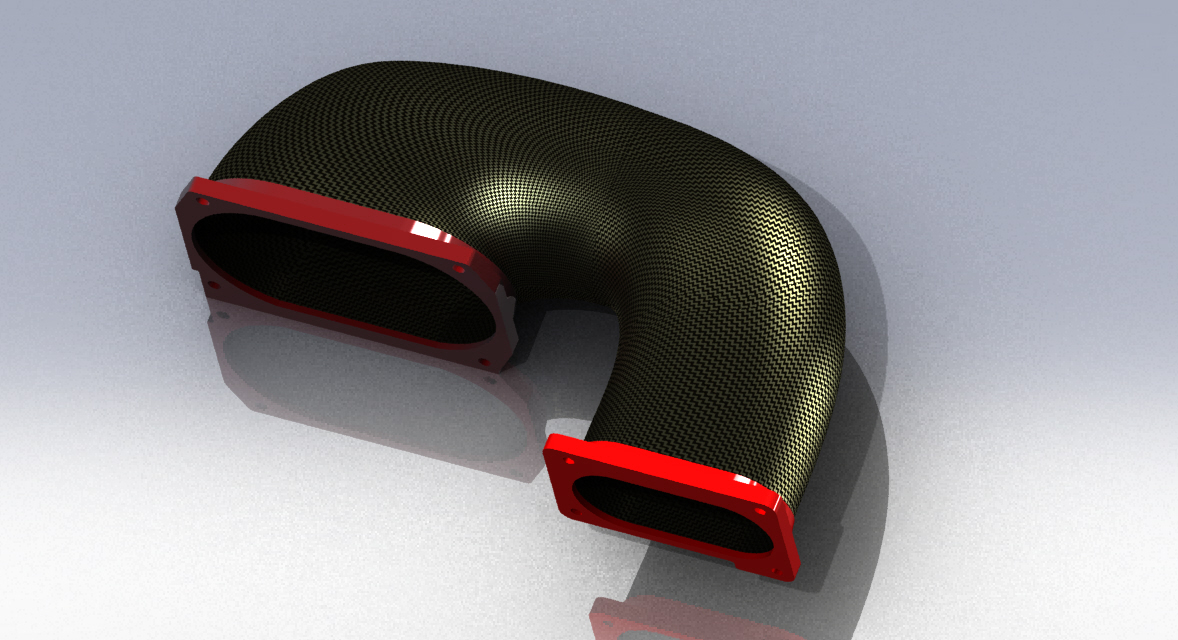

New Carbon Fiber Elbow Design! Started May10/11

Vacuum baging first part! 8 layers of

10.9oz 8HS CF

Perfect Vacuum! 28.5"

Lower half out of mold

weighing only 0.6lbs

Carbon Fiber back ordered waiting for more

to complete the lower half!

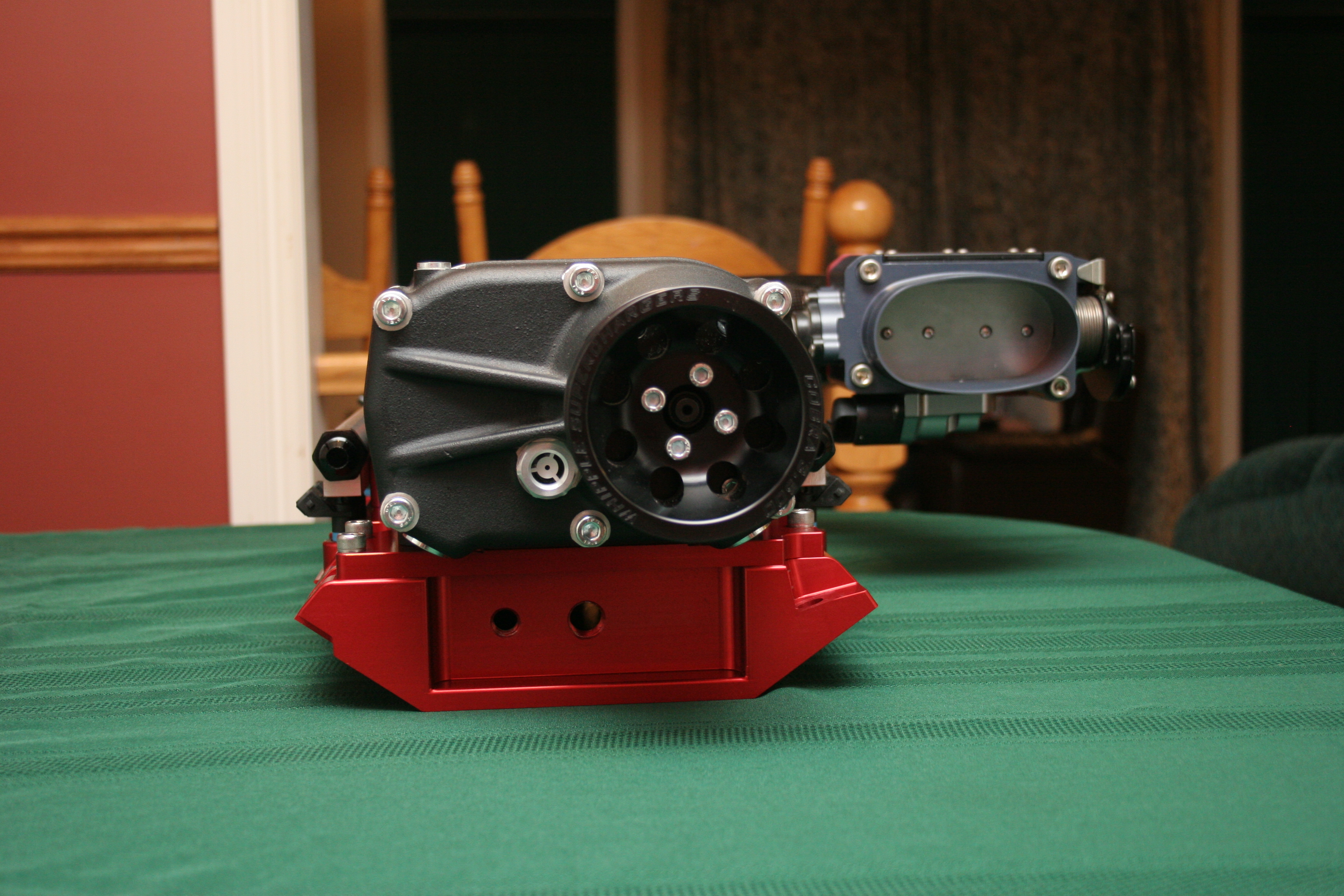

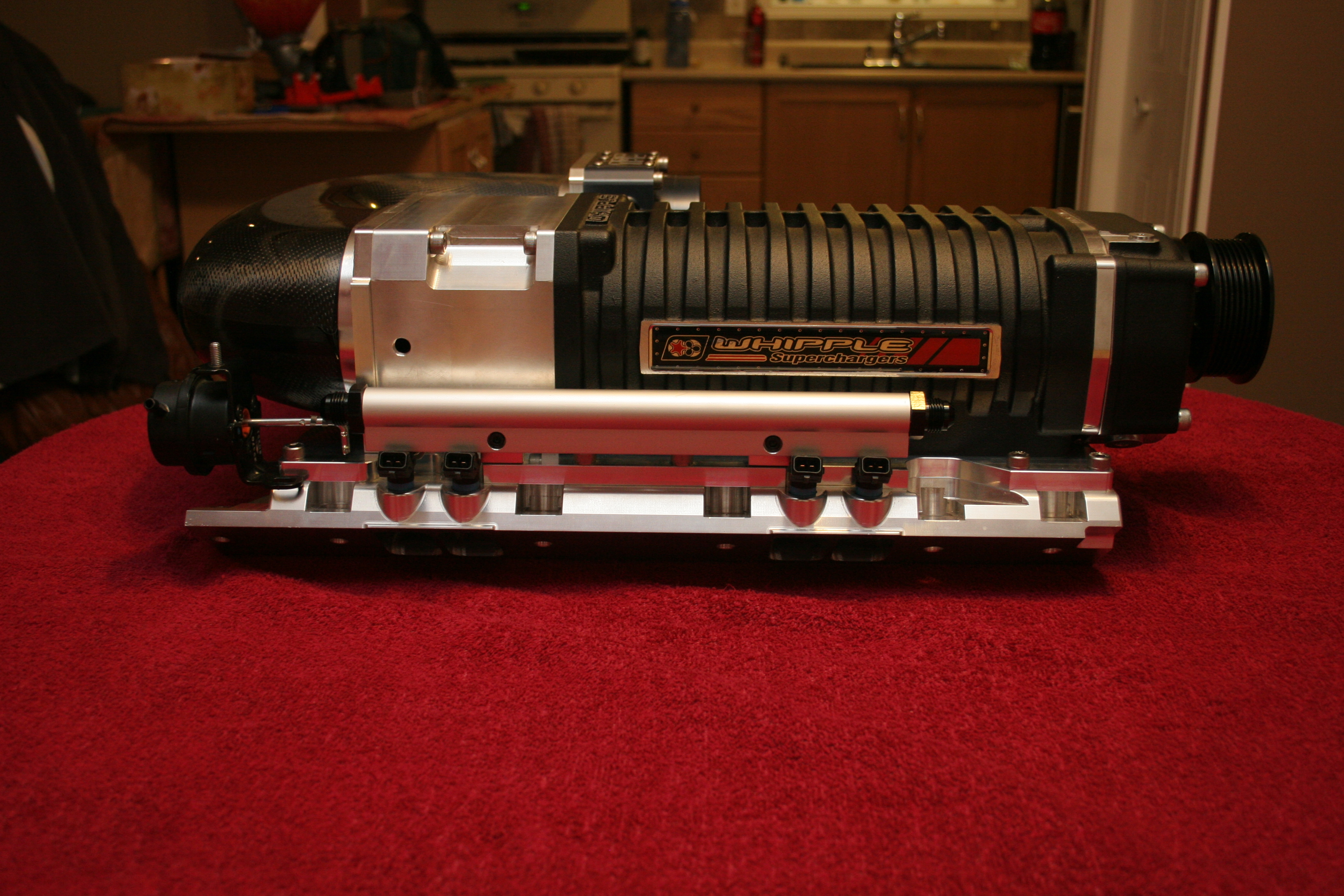

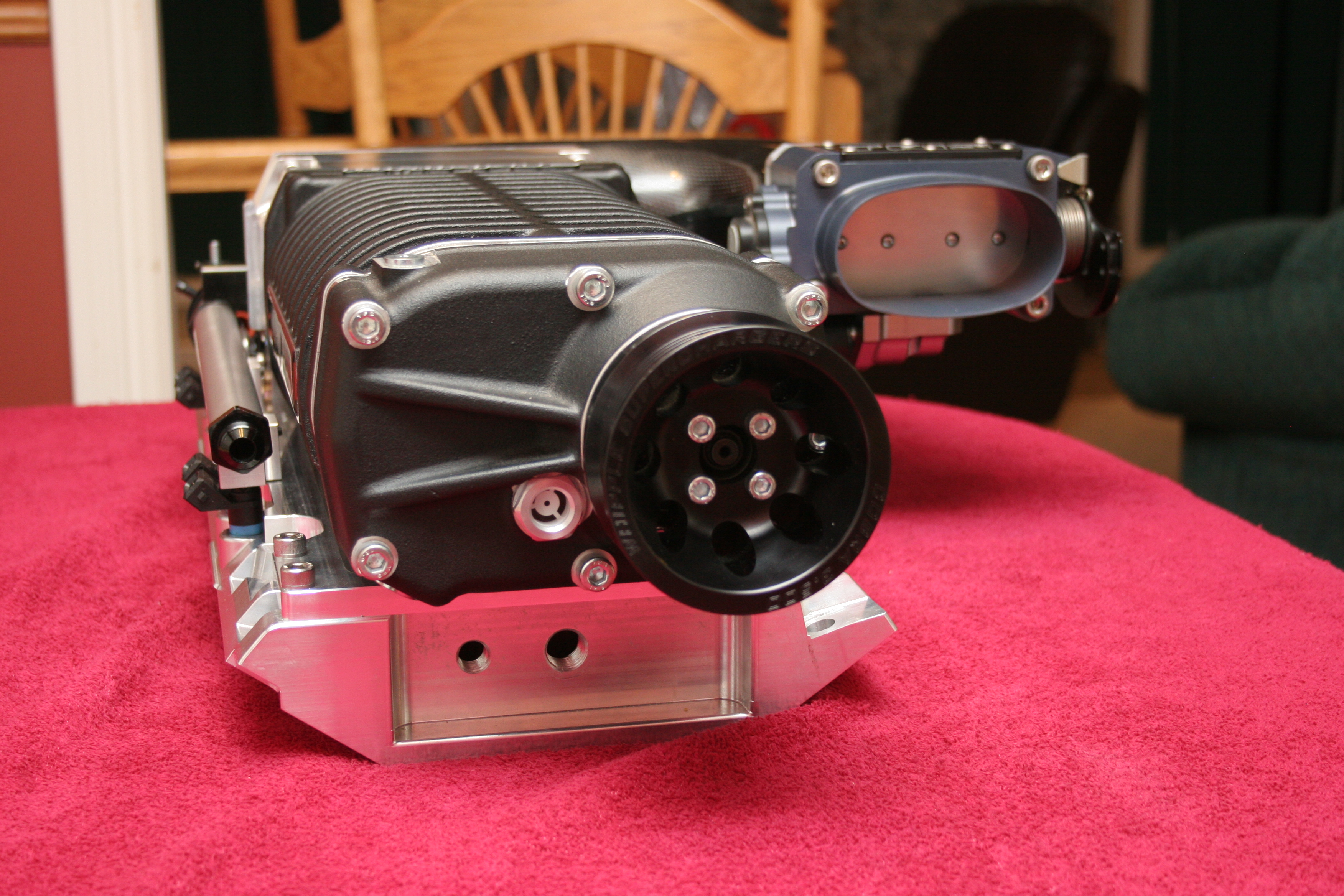

LT1 with

Whipple Supercharger

New

CNC'd manifold.

April

8/11

This the start of phase II

I am currently building a new engine capable of handling ~1000hp. I won't

really get the chance to try this since I am shooting for something less 650-750

hp rear wheel.

I am going to use my new intake design with a Whipple 175ax supercharger.

No K-Member spacing is required or hacking or cutting. This fits under the stock

hood!!!

The long block is being built by D,Sousa performance in Milton Ontario. This

engine is far from taxing his expertise in the performance world.

The build so far for the LT1 is as follows.

Phase II LT1 with Whipple 175AX

-Stock LT1 Block machine .030 over 4" bore

-3.48" Eagle 4340 crank = 355cuin.

- JE extreme duty blower forged -22cc pistons

- 8.9:1 Compression Ratio

-5.7" Eagle ESP H-Beam rods with L19 ARP bolts.

-Eagle 4 bolt splay caps with ARP Fasteners

-Moroso Oil pan #20185

-M55HV oil pump

-ARP oil pump drive

-Total-Custom custom blower rings

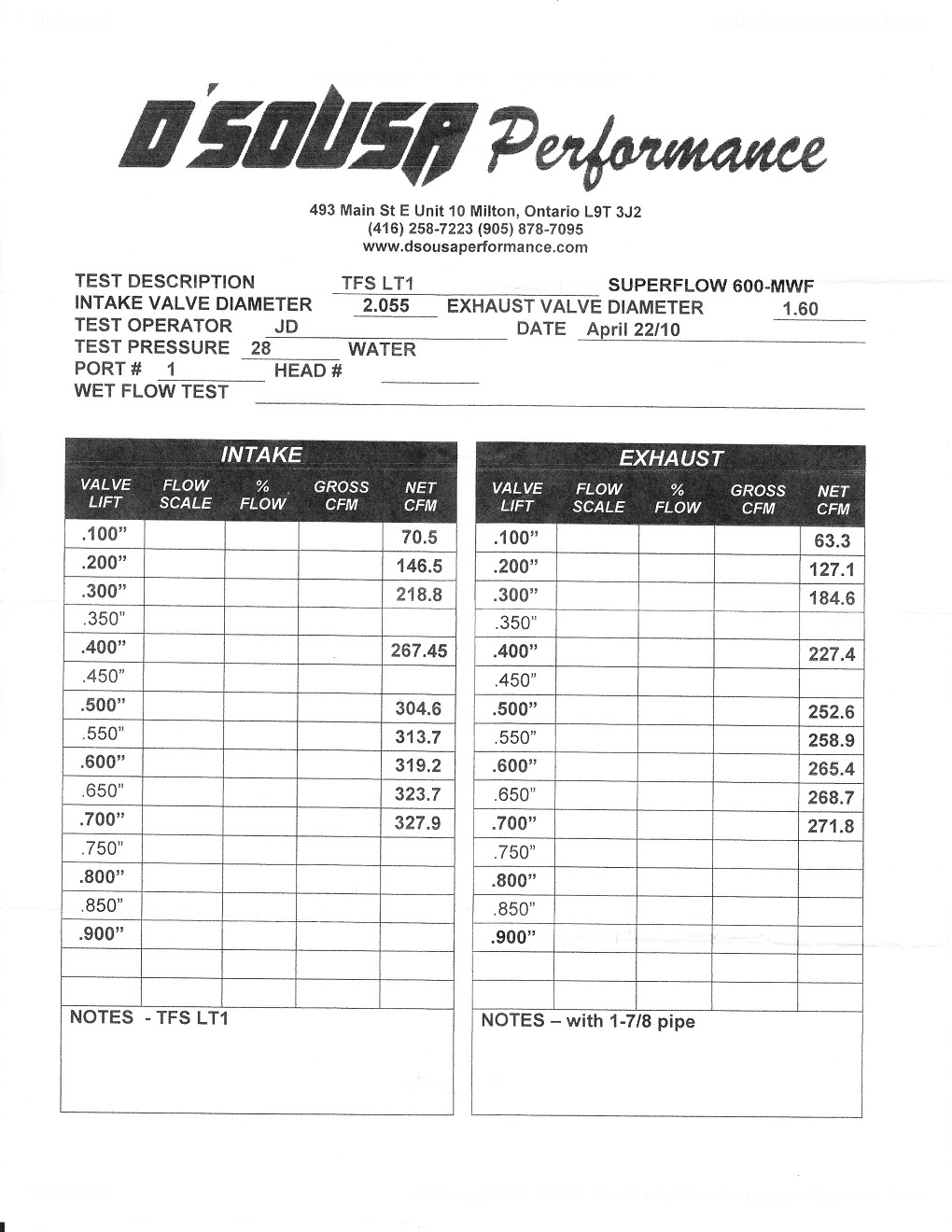

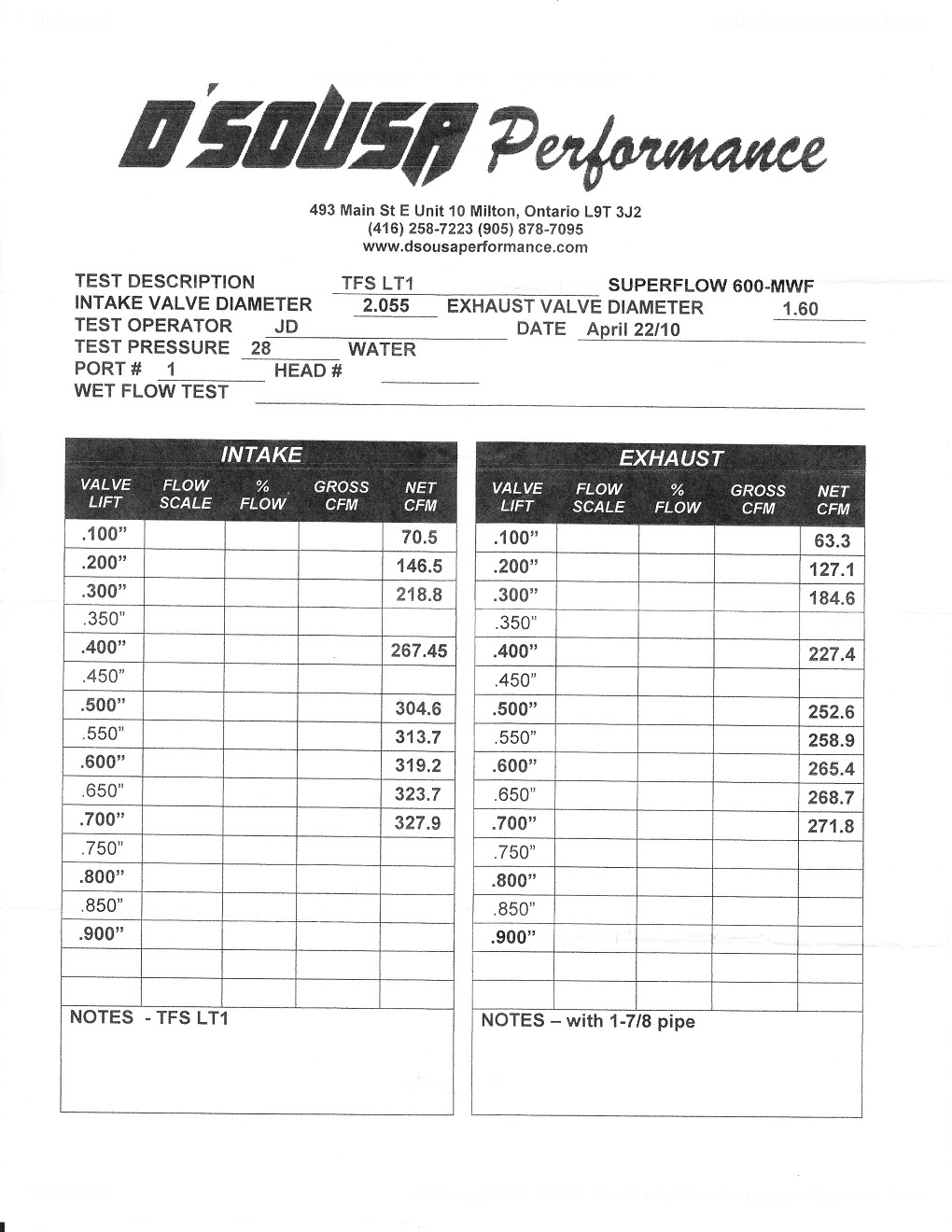

-Trickflow heads (~68cc chamber )custom full CNC. Flow#'s?

-Cometic head gaskets and ARP studs

-EFI Connection LS1 computer conversion with custom 3

bar hp tuners OS and real-time tuning.

-EFI Connection custom CNC timing cover for clearance of

double roller chain and reluctor ring.

-Timing Chain - Cloyes Premium Billet True Set

# 9-3645X9 9 position adjustment. *note* Top gear is .100" thicker

than stock and

must modify EFI Connection cam sensor housing and cam

reluctor!

-Corneltech custom CNC intake manifold and elbow with Whipple (2.9L)

175 AX 1" non-drive snout.

-Machined ATI balancer for 8-RIB belt and double keyed

crank

-3.5" cobra pulley upper with 7.5" lower crank (ATI)

-Headers Lamont Performance 1 7/8" stepped with

magnaflow cats welded in.( great headers!)

-Rear Axle ford 9"

-Rear Axle Ratio 3.55's

-Crower custom grind cam 232 int. 238 exh.

.622 .624 lift 114 LSA

-Melling 25% HV Hp pump with ARP drive Shaft and hardend steel oil pump drive gear

*The first manifold is being machined right now!*

Pictures

|

|

|

|

Block1

Block Machined .030 over and drilled for 4 bolt caps. |

|

|

|

Eagle 4 bolt Splay

Eagle 4 Bolt Splay caps with arp bolts |

|

|

|

|

|

JE Slug and ESP H-beam

JE extreme duty -22cc and Eagle ESP H-Beam with L19 ARP |

|

|

|

|

|

|

Eagle ESP H-Beam

ESP H-Beam with L19 ARP bolts |

|

|

|

One Tough Piston!

This JE Extreme Duty Blower piston is a Thing of beauty. Measures -22cc. Notice the extra web around the skirt! |

|

|

|

L19 Bolts

I guess better safe than sorry! |

|

|

|

Immaculate Shop! Engine Assembly Room.

Joe runs one damb clean shop. I dropped in unannounced to take these photos. Can you believe this place? |

|

|

|

|

|

Cap drool.

I'm just drooling over parts! |

|

|

|

Block pics

|

|

|

|

Block Pics

|

|

|

|

Block Pics

|

|

|

|

Partly assembled Bottom end

Feb3/2010 |

|

|

|

|

|

Flipped over view

|

|

|

|

Whipple 175AX

NEW WHIPPLE SITING ON OLD MANIFOLD |

|

|

|

Comparing M112 to Whipple 175AX

|

|

|

|

|

|

|

|

Inlet will be cnc'd to fit TB

|

|

|

|

|

|

|

Whipple is actually lower than the M112

|

|

|

|

|

|

Old set VS new

|

|

|

|

This is going to Haul the Mail!

|

|

|

|

3.5' pully to start with!

|

|

|

|

The manifold is going to be CNC'D

|

|

|

|

New Larger fuel rails

|

|

|

|

|

|

LS1 EFI connection conversion

This conversion will let me use a LS1 2-3bar tune using HP tuners. Notice the new CNC timing cover from EFI Connection. This will provide room for a cloyes DR chain and the reluctor ring nad sensors. |

|

|

|

The whole convesion kit coils and all!

|

|

|

|

CNC timing cover and 24x reluctor and 1x reluctor

|

|

|

|

|

|

|

|

Inside the cover

|

|

|

|

Clearance for 24x ring.

|

|

|

|

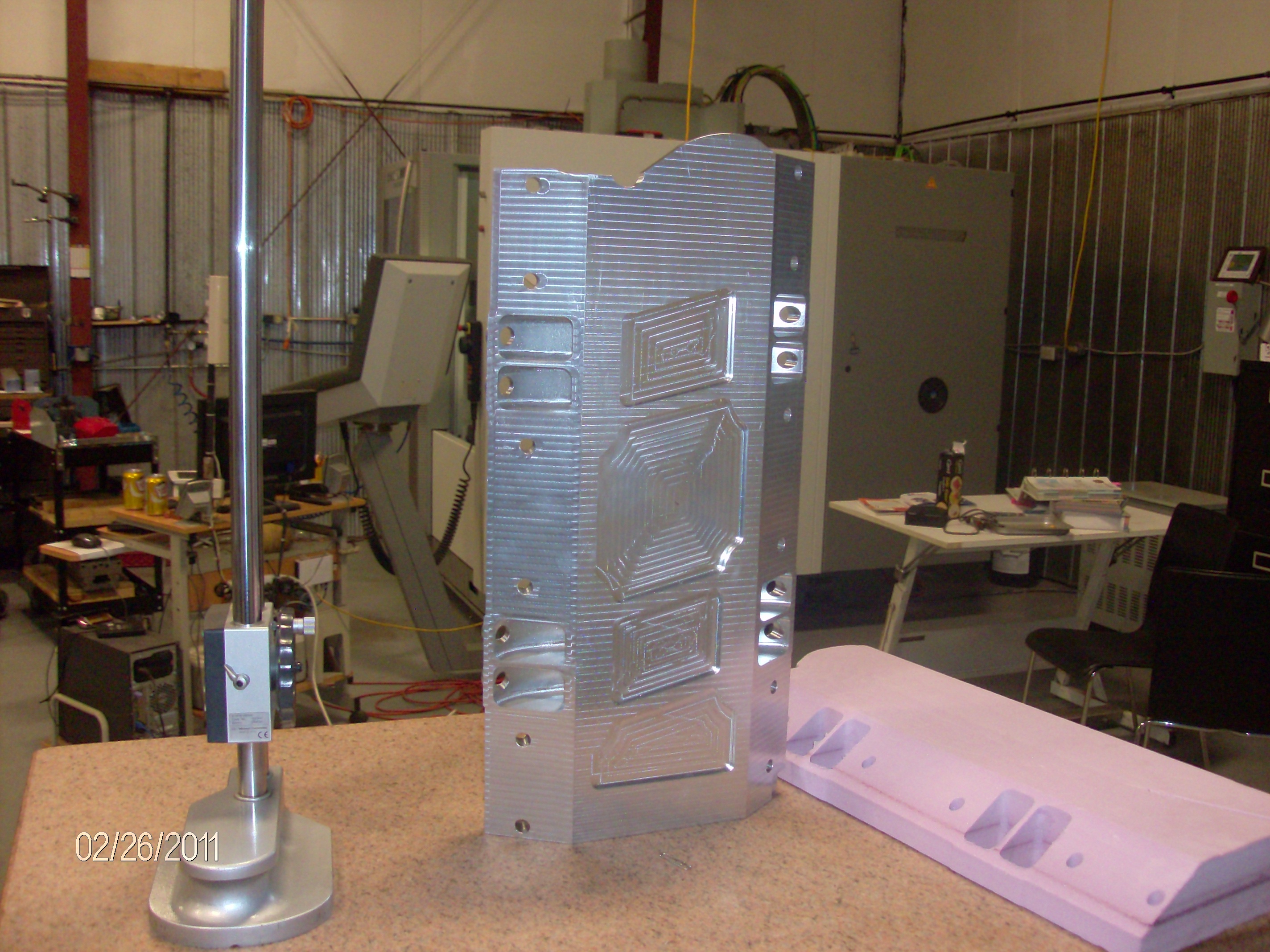

New CNC manifold design

Fitted with mockup Whipple |

|

|

|

New CNC manifold design

Fitted with mockup Whipple |

|

|

|

New CNC manifold

Fitted with mockup Whipple 175 |

|

|

|

|

|

New CNC manifold design

Fitted with mockup whipple 175ax |

|

|

|

CNC intake elbow as well!

|

|

|

|

Manifold with bypass

|

|

|

|

Manifold with bypass and rails

|

|

|

|

|

|

|

|

|

Custom CNC'd Trick flow 195s

Done by Joe D'Sousa |

|

|

|

These should make some power!

|

|

|

|

|

|

|

|

|

|

|

64cc chamber 2.055" int and 1.60" exh

|

|

|

|

|

|

|

EFI connection LS1 conversion 24X

Double roller timing chain |

|

|

|

Joe's Custom pickup for the Moroso Pan

|

|

|

|

clear view of the 24X

|

|

|

|

Oil pump and pickup

|

|

|

|

|

|

24X reluctor double keyed for SC drive

|

|

|

|

More Progress

|

|

|

|

|

|

New front end K-member

|

|

|

|

|

|

Adjustable lower arms

|

|

|

|

Firebird waiting for new Whipple SC engine

|

|

|

|

Dropping out old K-Member

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Old K-Member

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shop Rules!!

|

|

|

|

Reinforcing Shop Rules!!*

|

|

|

|

Test Fitting

|

|

|

|

|

|

|

|

Me Power!

|

|

|

|

|

|

|

|

|

Bottom Shot

|

|

|

|

|

Cleaning up!

|

|

|

|

UMI K member

Engine tabs needed trimming to fit! |

|

|

|

|

|

|

Putting engine on K-member

|

|

|

|

don't drop it!

|

|

|

|

|

Milled out clearance for AGX shock

|

|

|

|

clearance visible here!

|

|

|

|

|

|

Checking Mcleaod twin disk!

Making sure to have correct clearance between middle plate and bottom disk .020-.025" |

|

|

|

Checking

|

|

|

|

.020"

|

|

|

|

Twin Disk!

|

|

|

|

|

|

|

|

Clearance issue with k-mem and LPP header!

Trim and paint k-member |

|

|

|

Install T56

|

|

|

|

|

|

|

|

Lowering car onto assembly

|

|

|

|

Lowering car!

|

|

|

|

table on dollies!

|

|

|

|

It's in!

|

|

|

|

On the ground and loaded!

|

|

|

|

|

|

Can't wait!

|

|

|

|

Custom Cattedd LPP y pipe

I bought magnaflow cats and installed them into the LPP y-pipe. These headers are really high quality workmanship! |

|

|

|

bottom pics!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AC compressor 8 rib mod

I had my AC compressor modified from 6 rib to 8 rib. |

|

|

|

AC compressor 8 rib install

You can see the ATI and AC both have 8 ribs now! |

|

|